Warehouse Safety Ideas: 5 Steps to Reduce Risk

Discover simple yet effective methods of reducing the risk to employees working in your warehouse safety, creating a more secure working environment.

A safe warehouse environment is paramount to your business’s survival. If proper safety procedures aren’t in place, accidents can become commonplace in the warehouse environment. The scale of the workforce involved, the machinery used, the extensive use of racking systems and the size of the structure, along with the often heavy items contained within it, all add up to a workplace that is inherently hazardous.

Health and safety problems that result in worker injury or death can destroy a business.

Across the globe, forklift operation regularly ends in injury or fatality in America alone, 20,000 people are injured by the vehicles each year. Here in the UK, each of the top five most common causes of workplace fatalities has the potential to be caused by the warehouse environment. These are falling from a height, being struck by a moving object, getting hit by a moving vehicle, being trapped under collapsed equipment (such as racking) and death by workplace machinery.

Unfortunately, accidents are sometimes unavoidable. However, there are plenty of steps businesses can take to avoid health and safety breaches that result in legal liability, and live up to ethical codes that mean their workers are secure in their environment.

At Storage Equipment Experts, we are specialists in warehouse safety. We’ve travelled the length and breadth of the country and seen every kind of setup there is. With that knowledge in mind, here are our top five warehouse safety ideas to reduce the risk of accident or injury:

1. Create a Clear Movement System

Warehouses are notorious for containing big pieces of machinery, large crates, and rows and rows of shelving and racking. Navigating this environment can be tricky, especially without a clear line of sight. Such obstacles greatly increase the risk of collision between workers.

This kind of problem can be negated by creating a movement plan. Similar to a road or car park, create a structure of mobility that means you can only move in certain directions through certain areas of the warehouse. These could be one-way passages or the creation of lanes.

By creating a clear path of movement, you reduce the chance of collision by making sure everyone is moving in the same direction. Sign post this warehouse safety idea clearly. Make sure the layout is not only intuitive and easy to follow, but that there is always visible information available about what the flow of traffic is for those who aren’t familiar.

2. Racking Inspections by SEMA Approved inspectors

Racking fills warehouses. Sometimes it can cover near every inch of available space.

Racking houses all your goods and is an essential piece of equipment workers will regularly come into contact with. It is also made of heavy materials and holds heavy objects, some of which can be found at great height.

Unstable or damaged racking has the potential to cause serious injury or worse. The HSE, the British governing body of health and safety enforcement, recommends that qualified inspectors carry out racking reviews at least once a year. We are also strong advocates of this advice.

Ensuring your racking is secure can avoid a lot of preventable problems. Wear and tear, damage and poor initial construction can lead to weaknesses in racking, which in turn can lead to falls, collapse and instability, putting workers at risk.

Hire a SEMA approved racking inspector, such as us at Storage Equipment Experts, to make sure your warehouse racking is safe to use.

3. Eliminate All Clutter

Any unnecessary clutter has the potential to be a trip hazard, cause entanglement, result in somebody becoming trapped or cause injury due to falling objects. These are dangers that can easily be avoid by presenting workers with a strict policy on maintaining a clean and clear working environment.

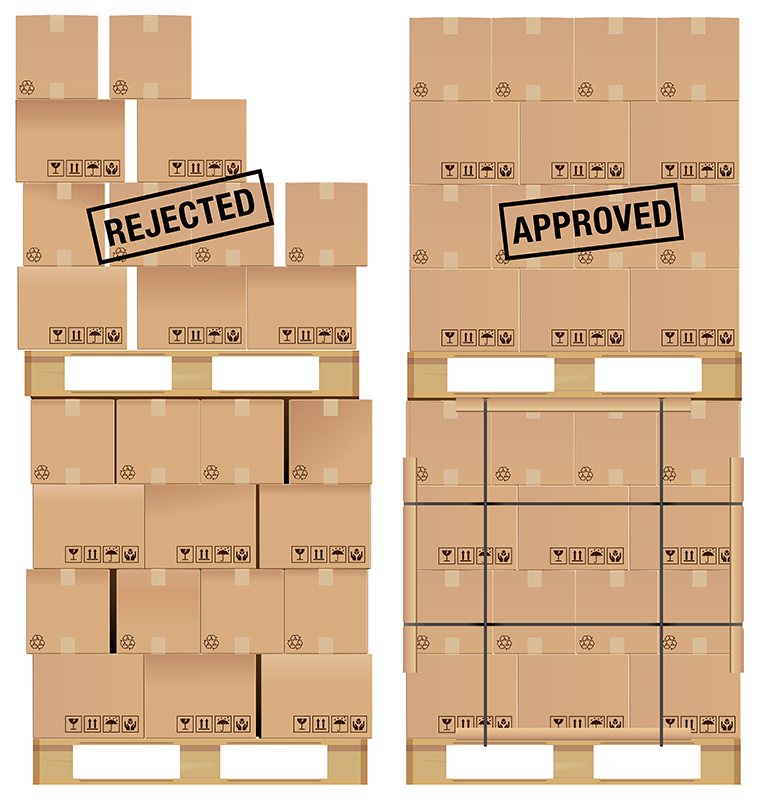

Line of sight is essential to avoiding many warehouse problems, as is organisation. Create a strategy that ensures everything has an assign place to be stored and that storage is done properly without creating a jumbled mess. A mountain of misaligned crates is a disaster waiting to happen. If there is no place for appropriate storage, allocate areas of the warehouse for objects to be place out of the way of usual activity until a secure, permanent home can be found.

4. Employ Automation and Smart Tech

According to HSE, falls from height are the second highest cause of death in the workplace. This isn’t particularly surprising, since working from a height carries great risk. However, there are ways you can reduce the need for employees to carry out work at a height, and this starts with smart technology.

Drones are slowly being introduce to warehousing as automated tools for stock checking. The technology is program to check for items, locate packages and even transport them, if possible. This means your workers don’t have to reach high places to identify or move stock.

There are other ways you can utilise smart tech for warehouse safety. Amazon recently patented a device which tracks hand movements and directs employees to the right place, helping them to avoid moving the wrong items or items they don’t have the equipment to hold. Tracking movements also allows you to monitor employees and ensure they are following safety regulations properly.

5. Educate Everyone on Warehouse Safety Ideas and Rules Regularly

Things change, workplaces evolve, new people arrive and people get complacent. Due to the adaptive nature of work and warehousing, a one-off training process in safety is not sufficient. Reminders and updates are require to keep workers on their toes and ensure they are following the correct procedure. Provide regular training sessions that refresh key skills and safety information. If new systems do come into place, make sure everyone is aware and up-to-date.

Time to up your warehouse safety? Contact Storage Equipment Experts today to discuss how we can support your safety needs. Our SEMA approved racking inspectors ensure your warehouse equipment meets the standards defined by HSE.