Knowing how to stack pallets safely is an essential skill for running a warehouse safety.

If run a warehouse — or even if you run a business which deals with distribution and storage — you’ll likely have to deal with a lot of pallets. As such, you will need to know how to stack pallets safely. It sounds like a simple enough task, but there are a few common mistakes which business owners make.

Does HSE Have Advice on How to Stack Pallets Safely?

HSE has a lot of information on pallet safety in general, and stacking pallets is covered. Its guide to pallet safety is not a legal document, but it does refer to two laws: the Provision and Use of Work Equipment Regulations 1998 (PUWER) and the Management of Health and Safety at Work Regulations 1999. Following HSE’s guidance will likely mean that you are doing enough to adhere to those two pieces of legislation.

In this article, we’ve collected the advice from HSE’s document which is most relevant to stacking pallets specifically. When in doubt, businesses should always defer to HSE’s guidance, but this article is intended as a shorthand for the parts most relevant to stacking pallets safely.

How to Stack Pallets Safely With Five Easy Steps

1. Stack like with like

Because of the way the modern world works, pallets are universal. Broadly, their sizes and dimensions are covered by the International Standards Organisation. The reason for this is that it makes trade easier. With everyone using similar pallets, you can transport a pallet of goods from South Korea to South Africa, without having to worry about whether both warehouses will be using pallets.

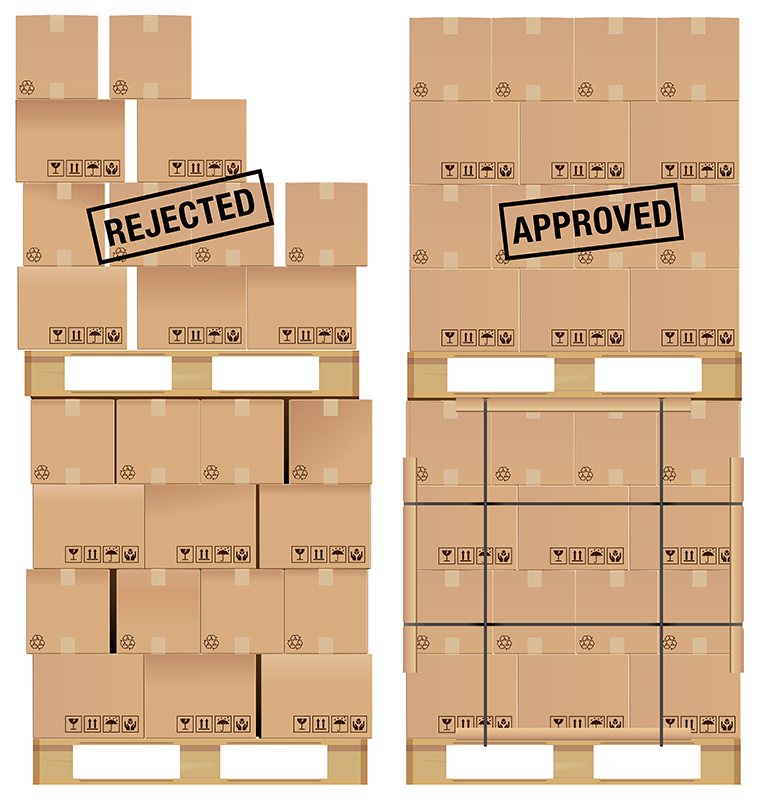

As great as this system is, it has its flaws, the chief one being that the sizes and dimensions of pallets are only “broadly” similar. Not realising this, many warehouse owners and business owners make the mistake of stacking all pallets together — regardless of their differing shapes.

For obvious reasons, this is not how to stack pallets safely. The safe way to stack pallets of different sizes and dimensions is to separate them into piles which all contain the same kind of pallet. However, you need to be more thorough than that. Plastic needs to be stacked with plastic, metal with metal, and wood with wood for the ideal system.

2. Don’t Lean Pallets on Their Sides

Pallets need to be stacked vertically on top of each other because that’s how they’re designed. As such, stacking a pallet on its side means running counter to the manufacturer’s intentions. Doing so means that you — not the manufacturer — are responsible in the instance of injury.

Injuries are indeed likely to happen to happen when pallets are stacked on their side. Removing one for use could cause another to fall, or someone could trip on a pallet stacked awkwardly. For more information about the latter, refer to HSE’s guidance document on preventing slips, trips, and falls.

3. Make Sure Pallets are Stacked at the Right Height

Knowing how to stack pallets safely depends on who you ask. In the United States, OSHA lays out detailed recommendations on how high a stack of pallets should be. However, in the UK, HSE defers to the manufacturer. Even still, it’s general guidance is that the height of your stack should not exceed the length of the base. In other words, if your stack resembles a cube, you’ve reached your upper limit. If it resembles a tower, it’s already far too high.

4. Never Use Damaged Pallets

This is a no-brainer covered by PUWER 1998, but it’s easy enough to forget with pallets. Pallets aren’t the goods themselves, so damage to them isn’t considered an issue. While this is true to a certain degree, damage to pallets does matter in the sense that those damaged pallets are not fit for reuse.

Like all other work equipment, you should perform regular pallet inspections. HSE recommends inspecting pallets after each delivery, which is in line with PUWER 1998’s statement that inspections should occur in any instance where work equipment is liable to be damaged. A delivery — any delivery — is liable to damage a pallet. As such, an inspection should take place after every delivery.

Damaged pallets should be repaired if possible. If not, they should be disposed of and the materials recycled.

5. Don’t Forget About Your Pallet Racking

As a final word of advice, be sure not to forget about pallet racking. Knowing how to stack pallets safely is important, but your pallet racking should also be safe. Without well-maintained and regularly inspected pallet racking, even the best stacked pallets could be unsafe.

HSE recommends regular inspections performed by warehouse staff and inspections every 12 months from an expert, such as a SEMA approved racking inspector. For the former, Storage Equipment Experts performs racking inspection training at a training centre in London or at your workplace — anywhere in the UK or Ireland! Storage Equipment Experts also provides racking inspections by SEMA approved inspectors for businesses across the UK and Ireland.

To book your racking inspection or training run by a SEMA approved racking inspector, contact Storage Equipment Experts today.