SEE Offer the Biggest Range of Racking Inspections Services in the UK!

From rack safety inspection checklists to pallet racking inspections training, Storage Equipment Experts offers the most diverse range of racking inspection services anywhere in the country.

There are many different racking inspection services in the UK, but only ours offers such a large range of services at such a high quality and reasonable price. In fact, the cheapest services we provide are completely free!

A Warehouse Racking Inspection Checklist and a Blog Full of Information on Racking Safety… For Free!

One of the best value for money racking inspection services we offer is right here. The Storage Equipment Experts blog is an invaluable resource for anyone with any quick — but important — questions about racking inspections, warehouse safety law, and racking systems themselves. We offer answers to all the possible questions a warehouse owner might have.

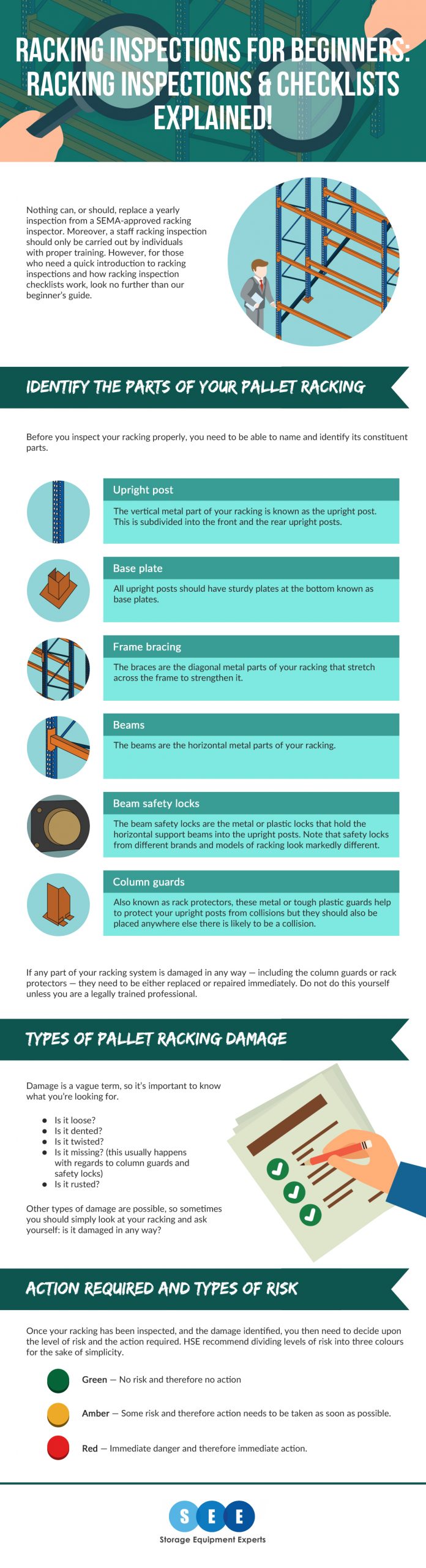

More than that, our warehouse racking inspection checklist is also available at the extremely competitive price of absolutely nothing! Your racking inspection checklist is the first step towards racking safety. Though it definitely shouldn’t be the only step…

Racking Inspection Services from a SEMA Approved Racking Inspector

At the heart of our racking inspection services are the racking inspections by a SEMA approved inspector we offer from our very own SEMA approved racking inspector (SARI). HSE recommends that warehouses receive an “expert” racking inspection from an independent racking inspection company at least once a year. HSE cite SEMA approved racking inspectors as an example of an organisation which certifies racking inspectors as experts.

In line with HSE’s advice, this is exactly the kind of racking inspection service we offer. No matter where your business is in the UK, we can promise to deliver a racking inspection by SEMA approved inspector for your warehouse to make sure that your company is on the right side of HSE.

Racking Inspection Training Services from a SEMA Approved Racking Inspector

A SEMA approved racking inspector can do more than just deliver racking inspection training; they can educate others on how to perform racking inspections themselves. This is another service that we offer at Storage Equipment Experts.

As per HSE’s advice, we believe that all businesses should be able to perform their own internal racking inspections on a regular basis alongside annual inspections from an independent racking inspection company. However, in order for staff and employers to be able to do this, we recommend using our free racking inspection checklist alongside our well-acclaimed racking inspection training.

Our customers state that our racking inspection services have helped to give their staff the confidence and the knowledge to inspect racking themselves. Confidence and knowledge are key. Without knowledge to inform your confident predictions, or the confidence to voice your knowledge, racking inspections are not the thorough safety routines that they should be.

Further Reading: Articles on Racking Inspections and General Business Safety

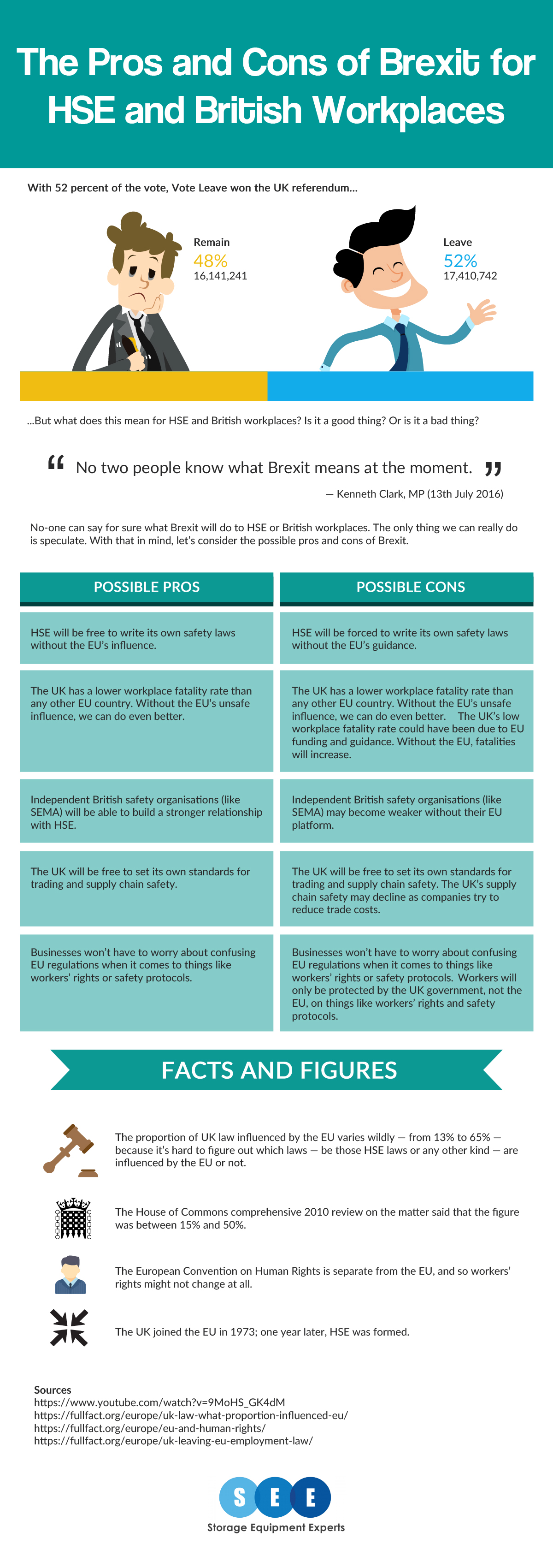

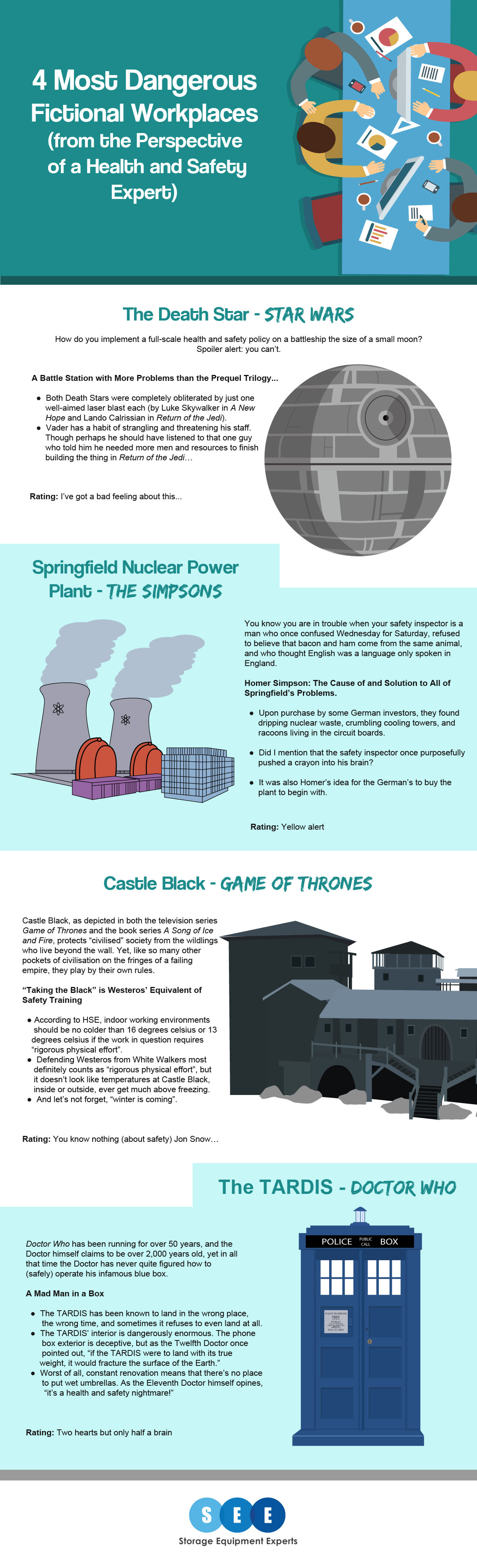

Taking our commitment to complete racking safety further than any other independent racking inspection company, Storage Equipment Experts founder — Justin O’Sullivan — has written articles for publications across the internet. These articles aim to educate business owners from around the world on warehouse safety and general workplace safety in an entertaining and informative way. We’ve been featured in British, American, South African, and Asian publications with articles on all kinds of workplace safety issues. These range from the workplace safety issues facing Japan, to the events of the SEMA safety seminar, to the important question of whether the TARDIS is a more dangerous workplace than Castle Black.

The reason small and big businesses use us is that we go above and beyond the call of duty in terms of racking inspection services. We are passionate about what we do and our passion is clearly evident in the range of services we offer. No other independent racking inspection company offers quite the same combination of range, quality, and value for many when it comes to racking inspections services.

Don’t try the rest; go for the best! Racking inspection services from Storage Equipment Experts are second to none, so contact us today for racking inspection training and a racking inspection from the most prolific SEMA approved racking inspector in the UK.