Everything You Need to Know When Preparing for a Warehouse Racking Inspection

Warehouse racking inspection safety is the top priority for most warehouse managers and owners, as any incidents that take place on the warehouse floor can have a serious impact on the health of staff, as well as interrupt operations for lengthy periods. One of the most important ways to ensure this is through regular racking inspections.

These inspections help identify potential hazards (like structural weaknesses) and any compliance issues before they become major problems. But how do you prepare for a racking inspection to make sure everything goes smoothly?

In this guide, we’ll cover everything you need to know to get your warehouse ready, minimise disruptions, and ensure your racking systems pass inspection with flying colours.

Why do Regular Racking Inspections Matter?

Before preparing for the inspection, it’s valuable to get an understanding of why the inspection is so important.

- Safety – Warehouse racking systems can pose a serious safety risk if they are not properly maintained. Inspections help identify and address issues like bent beams, loose bolts, and overloading.

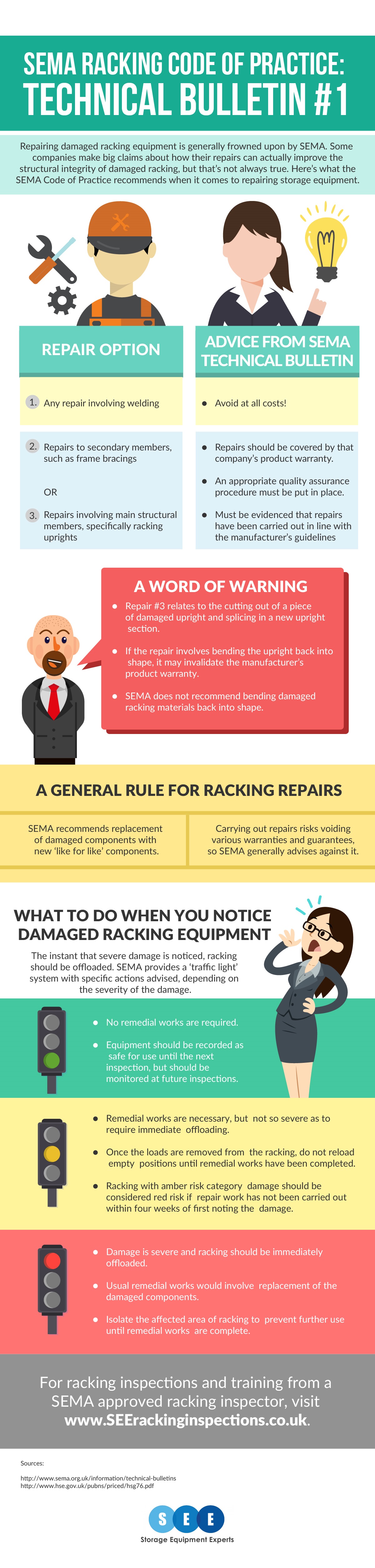

- Compliance – Regular inspections ensure that your warehouse complies with industry regulations and standards, such as those set by the Storage Equipment Manufacturers Association (SEMA).

- Efficiency – A well-maintained racking system reduces the risk of accidents, downtime, and operational inefficiencies. When racks are in good condition, your warehouse operates more smoothly.

Review Safety Standards and Regulations

The first step in preparing for a racking inspection is understanding the safety standards and regulations that apply to your warehouse. This will vary depending on the type of racking systems you use. Familiarise yourself with:

- SEMA Codes of Practice: A SEMA racking inspection is the recognised industry standard for racking systems in the UK, covering everything from load limits to rack construction.

- Manufacturer Guidelines: Every racking system comes with specific safety guidelines from the manufacturer. Make sure you know these inside out.

Understanding these regulations and standards helps you stay compliant and ensure your racking systems are up to code.

Conduct a Pre-inspection Walkthrough

Before the formal inspection, conducting your own pre-inspection walkthrough can help you identify and address potential problems in advance. During this walkthrough, focus on key elements that inspectors typically evaluate:

Structural Integrity

- Check for bent beams, dents, or any signs of damage on the racks.

- Look for any loose bolts or fasteners, and make sure that all connections are tight and secure.

- Inspect vertical uprights to ensure they are not leaning or misaligned, as this can affect load distribution.

Load Limits

- Verify that each rack is loaded within its maximum weight capacity as indicated by the manufacturer.

- Ensure that all load-bearing items are evenly distributed across the rack to prevent overloading or imbalanced weight.

Rack Alignment

- Make sure that all racks are properly aligned and that aisles are free of obstructions.

- Ensure that racks are anchored securely to the floor and that there are no signs of shifting or instability.

Organize Your Documentation

During the inspection, you’ll likely need to provide documentation that shows your racking system is being maintained properly. Being prepared with the right paperwork can make the process go more smoothly.

Key documents to have ready:

- Previous Inspection Reports: These provide inspectors with a history of your racking system’s condition and any past repairs or issues.

- Maintenance Records: Show proof of regular maintenance, including repairs, replacements, and safety checks.

- Load Capacity Specifications: Keep records of the manufacturer’s load limits and ensure these are easily accessible for the inspector.

Store all documentation in a centralised location that the inspector can easily access. Using digital copies can be helpful for quick retrieval, but it’s also a good idea to have printed copies on hand, just in case.

Being organised with your paperwork helps during the inspection and shows that your warehouse is diligent about safety and compliance.

Train Your Employees

Your employees are the ones who interact with the racking system on a daily basis, so their knowledge and behaviour play a key role in the success of any inspection. Proper racking inspection training ensures that they know how to use the racking system safely and can help prevent accidents or damage.

Focus on these key areas in employee training:

- Weight Limits: Ensure that all employees understand the importance of not exceeding the weight limits on racks. Make sure they know how to determine load capacity for different racking systems.

- Proper Stacking: Train employees on how to stack items correctly to avoid imbalanced loads or damaged products.

- Equipment Handling: Forklifts and other heavy equipment can easily damage racking systems if not used carefully. Make sure all employees are trained in proper equipment use, particularly when loading or unloading pallets.

Ongoing training is important, so consider holding regular refresher courses to ensure all employees remain current on the latest safety procedures.

Schedule Routine Maintenance

Regular maintenance is one of the most effective ways to ensure that your racking systems remain in excellent condition between inspections. Scheduled maintenance helps catch problems early before they become more significant and more expensive to fix.

This should include:

- Visual Inspections – Schedule weekly or monthly visual inspections where you check for any signs of wear, damage, or instability.

- Pallet Placement – Ensure that the pallets stored into the racks are the correct size and type, free from damage, stored correctly onto the racking and goods are secure onto the pallet.

- Floor Anchoring – Ensure that the racks remain securely anchored to the floor and check for any signs of shifting or movement.

- Cleaning – Clear the aisles and space around the racking systems to prevent dust, debris, or misplaced items from causing issues.

A regular maintenance routine helps keep your racking systems safe and in optimal condition for day-to-day operations and inspections.

Address Issues Immediately

Once the inspection is complete, review the inspector’s report carefully. If any issues are highlighted, it’s essential to address them as soon as possible. If any urgent safety concerns are identified, make these your top priority and fix them immediately. For non-urgent issues, develop a timeline and action plan for repairs, replacements, or adjustments, and once the necessary repairs are complete, consider scheduling a follow-up inspection to ensure everything is in compliance. You can avoid costly penalties and ensure your warehouse remains a safe and efficient work environment by being proactive. Find out more by visiting SEE Racking Inspections today!