Does HSA Recommend SEMA Racking Inspectors?

We provide racking inspections by SEMA-approved racking inspectors for businesses across Ireland..

Though it never mentions racking inspectors specifically, Ireland’s Health and Safety Authority does indirectly recommend SEMA racking inspectors. To understand how this is the case, it’s important to look closely at HSA’s advice.

HSA and Legislation

HSA’s website contains a list of all the legislation which pertains to health and safety in Ireland. It doesn’t have all the legislation in full on the website, but the most important piece of legislation is there: the Safety, Health and Welfare at Work Act 2005. This cornerstone act addresses various issues; however, it does not specifically reference SEMA racking inspectors or warehouse safety. It does, however, refer to the EU law which HSA is obliged to follow.

The EU’s guide on Steel Static Storage Systems recommends racking inspections from experts and competent staff at least once a year. Because Ireland is a member of the EU, Irish businesses are expected to follow this advice. However, the guide does not outline exactly what the EU means by “experts” and what qualifies as “competent” staff. This leaves many Irish businesses at a bit of loss.

Are SEMA Approved Racking Inspectors “Experts”?

England’s own health and safety board, HSE, claims that they are. In its guide to warehouse safety, HSE cites racking inspections by SEMA approved racking inspectors.

It’s true that HSE is the health and safety body for the UK, so its advice doesn’t necessarily have to be followed by Irish businesses. However, when it comes to warehouse safety, HSA itself refers to HSE’s advice. On its page addressing warehouse safety, HSA directs readers to the exact HSE guide which labels SEMA approved racking inspectors as experts.

So, Does HSA Label SEMA Approved Racking Inspectors “Experts”?

Irish businesses need racking inspections from a expert at least once a year in order to follow the EU’s advice. In the absence of other advice or indication as to who qualifies as a racking inspection expert, it’s fair to assume that HSA would consider SEMA approved racking inspectors experts.

In short, the advice from HSA is not very clear. However, when HSA’s advice is taken in combination with the EU’s advice, it becomes clear that SEMA approved racking inspectors do qualify as racking inspection experts and that all Irish warehouses should have racking inspection at least once a year.

A Few More Reasons Irish Businesses Need SEMA -Approved Racking Inspectors…

At Storage Equipment Experts, we offer SEMA racking inspections from a SEMA approved racking inspector. In other words, we offer “expert” inspections from an “expert” inspector. However, alongside this, there are a few other reasons why Irish warehouses should have racking inspections from us:

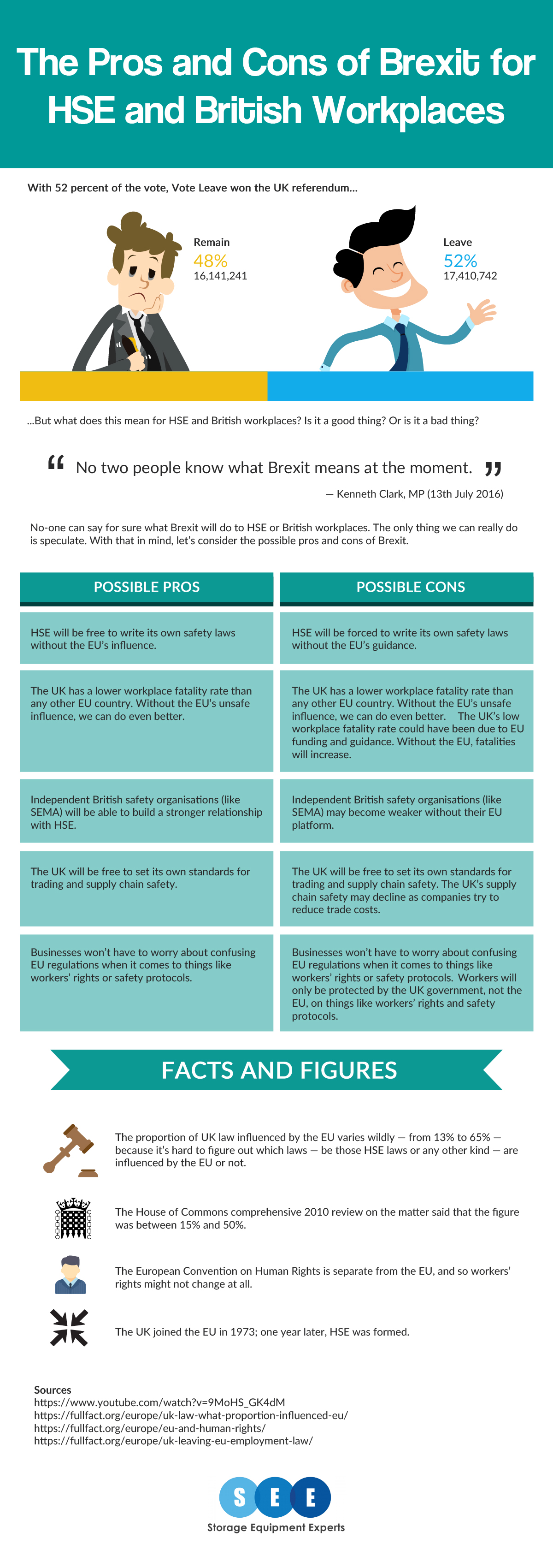

- As of 2017, both Ireland and the UK are still members of the EU. Even when the UK does leave the EU, its EU-influenced racking inspection legislation will likely not change. This means that the laws regarding warehouse safety are very similar in both countries.

- Both countries use similar pallet racking systems and have many other similar laws and cultural norms when it comes to safety. As a result, the warehouses and the racking systems are often the same.

- Ireland is extremely accessible from the UK and vice-versa. At Storage Equipment Experts, we offer UK-wide coverage and are more than happy conduct an inspection in Ireland, too.

- We also offer racking inspection training from a SEMA approved racking inspector for businesses that want their staff to be “competent” enough to perform the regular staff-led racking inspections that the EU and the HSE warehouse safety guide referenced by HSA both recommend.

If you’re still undecided about whether or not expert racking inspection services from Storage Equipment Experts are right for you, take a look at our testimonials page.

No matter where your business is in the UK or Ireland.

Get in touch with Storage Equipment Experts for a professional assessment by certified SEMA racking inspectors today. From our base in London, we’re happy to inspect warehouses anywhere in the UK or Ireland.