SEMA Rack Protection – Maximise Racking Safety

Minimising the possibility of damage to pallet racking is one of the most important challenges facing the storage industry and SEMA are very active in promoting the safe use of storage equipment.

One of the most relevant documents for the safe use of pallet racking is the ‘SEMA Code of Practice for the Use of Static Pallet Racking SEMA 2010.’ A complimentary copy of this code is available from SEMA for all End Users.

The SEMA Users Code has various requirements which will minimise damage including:-

- Person responsible for racking safety

- The User should nominate a competent person to be responsible for racking safety (PRRS).

- The PRRS is responsible for ensuring that the racking is used, inspected and maintained in accordance with the appropriate regulations and guidelines.

Operator Training To Reduce Racking Damage and Accidents

The User shall ensure that the operators are trained in the appropriate use and limitations of the storage equipment. It is the responsibility of the User to maintain the racking in reasonable condition. Comprehensive and effective driver training will minimise the possibility of any accidents.

Rack Protection

End frame protectors are recommended, in truck operated racking, for all end frames between a gangway and an aisle and also for all end frames between a bridge bay and an aisle. Other racking protection requirements should be considered as identified by the risk assessment. The User should be aware of the implications of retrofitting protection devices which reduce operating clearances and can, in some circumstances, lead to an increase in the amount of damage.

Inspection Requirements

Regular inspection of the pallet racking is required. The inspection should follow a hierarchical approach using 3 levels of inspection as follows:-

1. Damage inspection by warehouse operatives

2. Weekly inspections as a visual check from ground level

3. Annual or bi-annual inspection by a ‘technically competent’ person

Maintenance

Any damaged component, noted during inspection as requiring repair or replacement, should be taken out of use in accordance with SEMA guidelines and repaired or replaced by suitably trained personnel as required.

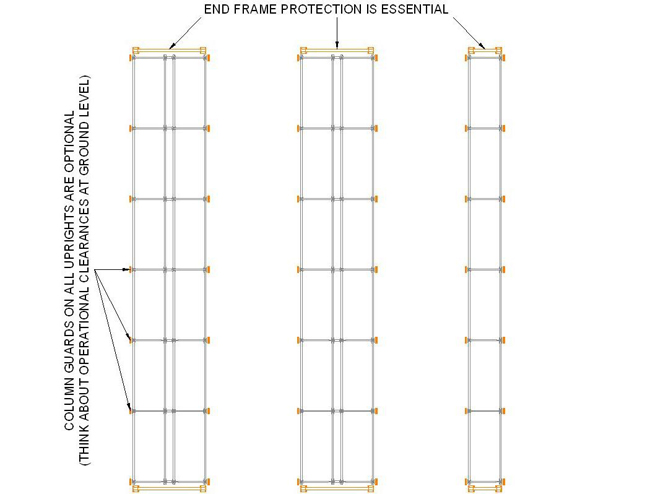

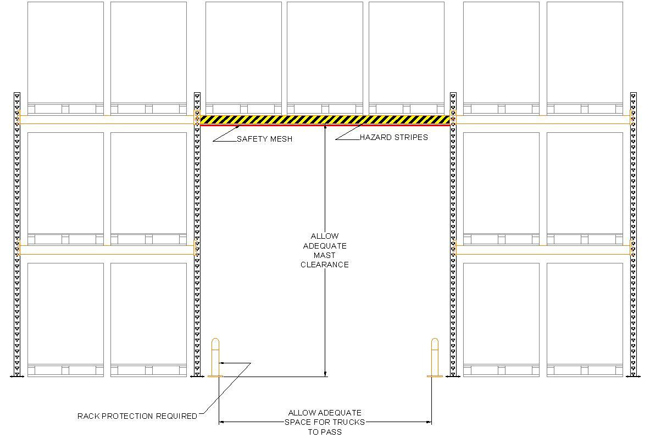

Typical racking protection requirements are shown in Figures 1 and 2.

Figure 1. Plan view of racking showing typical protection requirements

Figure 2. Elevation of racking showing typical protection requirements at a bridge bay

Another important document regarding the safe use of pallet racking is the HSE document ‘HSG 76, Warehousing and storage. A guide to health and safety.’ This can be downloaded free from the HSE website.

The HSE document has various requirements which will minimise damage including the following paragraphs on rack protection:-

Racking Protection Important In Reducing Risk

639 Where racking is likely to be struck by lift trucks and other vehicles, it should be protected. Generally, such damage is at the lower levels of the racking – use renewable column guards to minimise the risk of damage from accidental impact. Corner uprights in a run of racking are especially at risk and should be suitably provided with a protective device in a conspicuous colour.

640 Retrofitting upright protection devices to an existing aisle where they have never been provided can have the effect of reducing the available clearances for fork-lift truck manoeuvres, which can in some circumstances increase the amount of damage caused. Such situations need consideration on a case-by-case basis.

Unfortunately clause 639 is being interpreted that all racking uprights are likely to be hit and should therefore be protected by rack protectors and even that it’s the Law in the UK. This is not the correct interpretation of this clause.

Rack protectors should be regarded as a ‘last resort’ means of avoiding damage and other methods of damage prevention should be considered before taking the decision to use rack protectors.

The protection of racking is not just dependant on physical rack protectors, but relies on a number of items including:

- The specification

- The installation

- The defined responsibilities of the person responsible for racking safety

- The training of the operatives

- The inspection procedure

- The maintenance procedure

Items to be considered should include:-

- The type of damage to be protected against

- Whether other methods of protection are more appropriate

- The type of protector required

- Whether the protector will reduce clearances, potentially leading to more damage

- Whether the protector may hide potentially serious damage

- Whether the protector may lead to less reporting of damage

- Whether the protector may result in operatives using the protector as a buffer

The use of rack protectors should be carefully considered to ensure that it is appropriate and is not just a quick fix which may lead to further safety issues.

SEMA August 2012