What Are Load Notices?

Is it a Legal Requirement for Racking Systems to Have Load Notices in the UK?

According to HSE’s HSG76 Warehousing and storage: a guide to health and safety, all racking systems require load notices. HSE refer to SEMA as an example of how a load notice should look. This is because SEMA helped to develop the way most racking system load notices look today alongside the EU and HSE.

An EU Directive combined with HSE law and SEMA influence means that load notices legally need to look a certain way. In other words, all load notices need to be SEMA style load notices. If your racking system doesn’t have a load notice, you are running counter to HSE’s advice.

Is it a Legal Requirement for Racking Systems to Have Load Notices in Ireland?

In HSA’s advice on warehouse safety, they refer to HSE’s HSG76. HSG76 states that all racking systems require load notices. What is more, as a member of the EU, Ireland is also bound by the same EU directive on the way load notices need to look.

In short, much like in the UK, if your racking system doesn’t have a load notice, you are running counter to HSA’s advice.

What Should Load Notices Look Like?

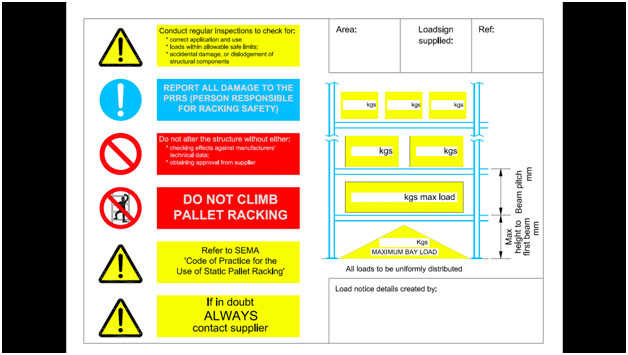

Load notices in the UK and Ireland should look as HSE, HSA, the EU, and SEMA recommend. For pallet racking systems, here’s an example of what a load notice should look like:

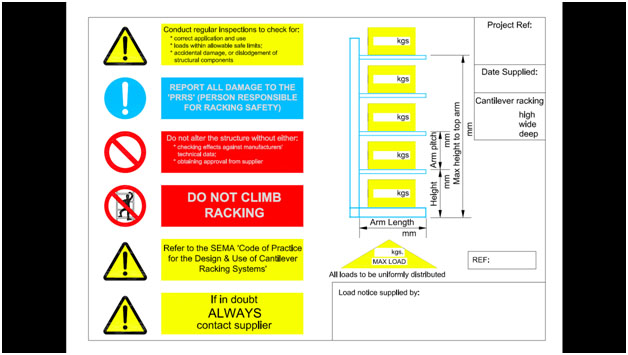

For cantilever racking systems, load notices should look like this:

Both notices follow the EU approved system. Red circular signs with white backgrounds and black pictograms are used for prohibition. Yellow triangular signs with black pictograms or text are used for warning. Blue rectangular signs with white pictograms or text are used for mandatory actions.

Not pictured is a green rectangular sign with white pictograms or text. Those are used for instruction, but a load notice doesn’t give any instructions because it doesn’t need to.

What Should I Do If My Racking System Doesn’t Have a Load Notice?

A detailed inspection of the racking system by a SEMA Approved Racking Inspector should be completed to assess the condition of the system before a load sign is displayed. Damaged or incorrectly installed racking will usually reduce the strength of the system and will no longer support the loads that it was originally designed for.

If you don’t have a load notice on your racking system, then you should contact the supplier of your racking systems. If the supplier of your racking also installed the racking then they should have information on the type and strengths of the racking and the configuration, all of which affect the load capacities of a racking system.

If the supplier of your racking systems is not available then you will need assistance to identify the manufacturer of your racking systems, the strengths/duties & dimensions of the various components within the system and accurately record the configuration of those components. Once this information has been collected, it can be used to work out the appropriate load capacities using information from the manufacturers technical specifications & data for the racking system.

Contact Us Today

We operate all over the UK and Ireland, so click here to complete our Racking Inspection or Training Costs form to receive a free quotation usually sent within 24hrs.