Don’t Stay Silent about Warehouse and Racking Safety!

Warehouse and racking safety requires carefulness, regular rack inspections, and workers who are free to speak up about potential problems.

Warehouse and racking safety is not a dogma; it is a dialogue between employees, employers, customers, safety experts, and the government. Everyone should have a say in how our warehouses can be made safer because warehouse and racking safety affects everyone.

However, while this is something which we at Storage Equipment Experts believe in, it is evidently not an idea shared by everyone. Workers at a supermarket distribution company were recently fired because they raised concerns over health and safety. Silencing whistleblowers does not help to make warehouses safer. The fear that employees are not allowed to talk about warehouse or racking safety leads to a culture of danger and worker exploitation.

The recent trial over the conditions at Sports Directs’ main distribution warehouse shows what happens when employees are not free to express their concerns over safety. Workers were pushed to the limit in extremely unsafe conditions and, as a result, the centre was forced to make 83 ambulance calls over the course of two years.

The Law Requires Safety Inspections: Warehouse Racking Inspections, Forklift Inspections, and Many Other Safety Inspections

Employers are legally obliged to ensure that their warehouse is being operated in accordance with HSE standards. These regulations are in place because they save lives and they should not be ignored. Employees should be encouraged not punished for raising health and safety issues, especially when those issues concern the law.

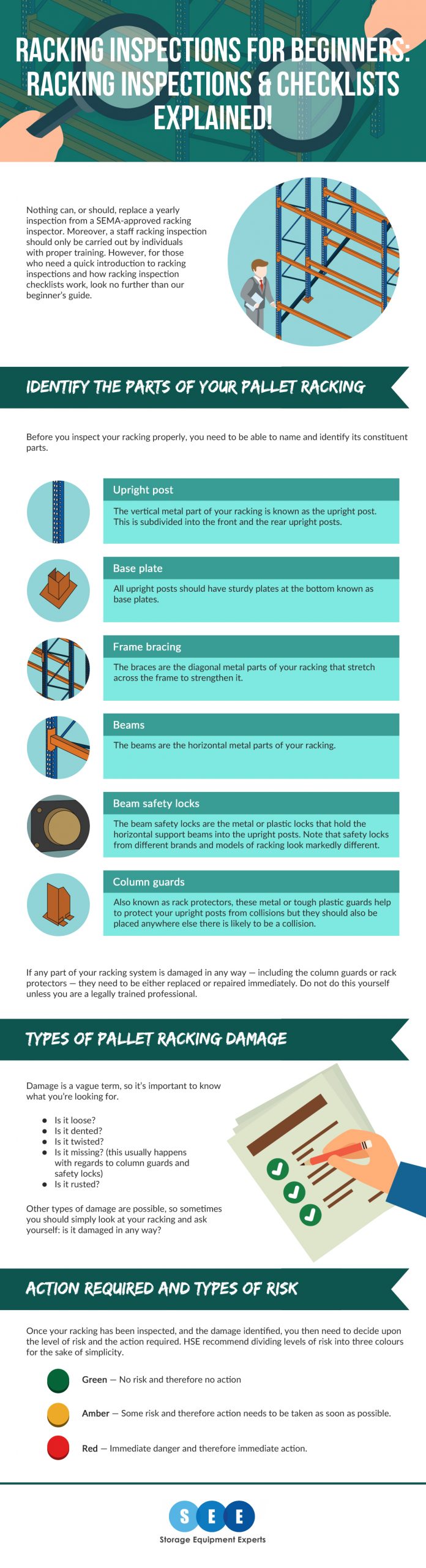

With regards to warehouse and racking safety, employers are legally required to make sure their racking is inspected by a safety expert a SEMA approved rack inspector at least once a year. Should an employee notice a problem, they should mention this to their employer. In fact, HSE encourages employers to conduct rack safety inspections of their own on a regular basis.

Employers should not be quiet about warehouse and racking safety. Rather it is both a legal requirement and good business — to make sure that they are actively involved in a frank and open discussion about warehouse and racking safety. This is why we provide racking inspection training from a SEMA approved inspector.

Safe, Smart, and Confident Employees are Better for Business

Businesses with employees who are educated on safety issues are better for several reasons. For a start, safety training of any kind helps to motivate employees as they feel more invested in and a bigger part of the team.

Both warehouse racking inspection training for small businesses and warehouse racking inspection training for big businesses have the psychological benefits that come from spending money on human capital. However, the other reason safer and smarter employees are better for business is cold hard cash.

Rack Safety Inspections Now Mean Bigger Profits Later

OSHA calculate that businesses who spend more on safety save money in the long run. Specifically, for every dollar a business spends on safety, they can save up to six dollars. This makes perfect sense. Rack safety inspections are a small expense, but the potential returns on this investment are huge.

After failing to adhere to warehouse safety standards, the international beer-giant Anheuser-Busch had to pay a jaw-dropping $162,000 fine.

A racking expert’s inspection could’ve prevented this expense. Ignoring warehouse safety may cost more than fines.

Casualties and in some tragic cases fatalities are the very real result of failing to invest in racking safety.

Businesses and their staff have no reason to stay silent about warehouse and racking safety.

Open dialogue on safety benefits the warehousing, logistics, and supply chain sector, fostering improved operations for all.

Don’t be silent and don’t ignore racking safety! Contact Storage Equipment Experts for a quote on your next warehouse racking inspection.