Damaged racking equipment and unsafe use of racking are the causes of many headaches. In severe cases, it can even be the cause of fatality. While identifying damage is much easier when staff have undergone racking inspection training, choosing the right remedial action can be tricky. Many companies offer repairs that supposedly improve upon the structural integrity of racking equipment, but their methods are often at odds with the SEMA Racking Code of Practice.

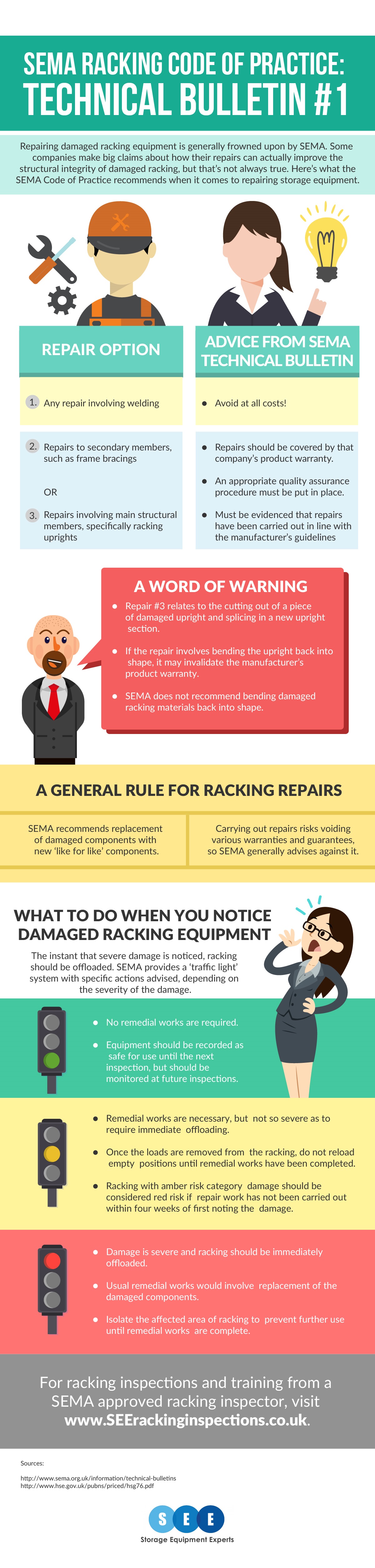

For the convenience of all warehouse operators, we’ve created an infographic guide to the SEMA Technical Bulletin No.

1. In it, we take a look at what the organisation advises when it comes to types of racking repairs, some general rules of thumb and a handy traffic light system for classifying damaged racking.

What SEMA Thinks of Different Repair Methods

The myriad of types of repair methods can lead to some confusion, so it’s helpful to see what the SEMA Racking Code of Practice advises in each case. Here’s what the SEMA Technical Bulletin No. 1 recommends:

- Repairs involving welding are to be avoided in all cases. SEMA does not mince its words here. The sole guidance it provides in relation to welding is as follows: “Such repairs are not recommended.”

- Repairs to secondary members, such as frame bracings, should be carried out in line with the manufacturer’s guidelines. They should also be covered by the repair company’s warranty and a quality assurance procedure must be put in place.

- For repairs involving main structural members, specifically racking uprights, the information is much the same as in the previous point. However, this repair should not involve the bending of uprights back into shape. Damaged areas of upright should be cut out and new areas spliced in.

Repairs should also be highlighted during racking inspections. Whilst some warehouses may require more frequent inspections, HSE’s HSG76 recommends a racking inspection frequency of once per year as a bare minimum. These inspections should be interspersed with regular checks from employees who have undergone racking inspection training, in order to keep an eye on racking safety in between expert inspections.

SEMA Racking Code of Practice: The Rule of Thumb for Repairs

While you could spend years studying the various pieces of racking legislation, SEMA Technical Bulletin No. 1 provides a couple of quick rules of thumb. Firstly, it strongly recommends replacing damaged components “like-for-like”. Scrimping on replacement parts may not only void your product warranty, but it may also endanger warehouse staff.

SEMA’s Racking Code of Practice also generally advises against carrying out repairs of damaged components. This doesn’t mean you should replace an entire racking system if become damaged; affected components should be spliced and replaced, rather than being bent back into shape or welded. According to SEMA, any repair that involves the bending of damaged uprights should be avoided.

It’s also worth bearing in mind that SEMA’s advice on repair is backed up by the law. The Provision and Use of Work Equipment Regulations 1998 emphasises the importance of repairing and inspecting work equipment, such as racking, whenever damage is suspected.

The HSE Traffic Light System

To assist with the troubleshooting of damaged racking equipment. HSE recommends a traffic light classification system which can be used alongside the SEMA Racking Code of Practice. Damage is ranked green, amber, or red depending on its severity, and appropriate actions are suggested for each category.

Green represents damage which does not require remedial work, but which should be monitored at the next racking inspection.

Amber refers to damage which should be remedied, but which is not so severe as to require immediate offloading. However, once loads are removed from this racking, the equipment should not be reloaded until remedial works have taken place. Racking with amber risk category damage should be considered red risk if remedial work has not been carried out within four weeks of first noting the damage.

Red represents severe damage and racking should be immediately offloaded. The normal course of action in this case would be to replace the damaged components with like-for-like parts. Racking with red risk category damage should be isolated to prevent inadvertent use and further risk to warehouse staff.

At Storage Equipment Experts, we know the SEMA Racking Code of Practice inside out. For racking inspection training from SEMA approved racking inspectors, get in touch today.