📍 North East England

Pallet Racking Inspections in North East England

Ensure the safety and reliability of your warehouse operations with our expert pallet racking inspections in North East England

Our SEMA-approved inspectors provide thorough, professional assessments to help you stay compliant.

Local Presence, Expert Support

Businesses across North East England trust our SEMA-approved racking inspectors to ensure compliance, safety, and smooth warehouse operations. Whether you manage a small storage facility or a large distribution centre, our comprehensive inspections identify potential risks before they become costly problems.

In addition to annual racking inspections, we offer rack safety awareness, racking inspection training, and ongoing maintenance support to keep your team confident, compliant, and safe.

Areas We Cover

We provide professional pallet racking inspections across North East England, including:

Why Choose SEE Racking Inspections in North East England?

Ensuring your warehouse operates safely and efficiently is vital to protecting your staff and assets. SEE Racking Inspections provides professional, thorough examinations to help businesses across North East England maintain compliance and reduce risk.

SEMA Approved Racking Inspectors

Our inspectors are all SEMA trained and certified, which ensures that the quality and reliability of inspection is at the top-level.

Fast and Flexible Inspection Services

We know that it is costly when the warehouse is down. We have quick-service and emergency inspections and our team is efficient to reduce the impact and continue with the usual operations.Clear, Actionable Reports

Every inspection comes with a detailed digital report complete with photographs and prioritised recommendations.

Supporting Local Businesses with Expert Knowledge

Our inspectors are fully familiar with North East England’s safety regulations. We also provide training, safety awareness sessions, and ongoing support to ensure your team.Complete Racking Inspection Services in North East England

We deliver tailored warehouse safety solutions to businesses across North East England. Our SEMA-certified inspectors ensure your storage systems are safe, compliant, and optimised for smooth warehouse operations.

Annual Pallet Racking Inspections

Scheduled inspections by our qualified SEMA inspectors help maintain HSE compliance and operational safety.

- Structural integrity of racks

- Checking load capacity

- HSE safety standards

- Detailed inspection reports

Damage Assessment & Safety Checks

Following collisions, forklift impacts, or visible racking damage, we conduct expert inspections to prevent further risk.

- Investigating incidents on-site

- Assessing severity of damage

- Safety improvements

- Guidance for urgent repairs

Warehouse Safety Awareness

Interactive sessions designed to enhance your team’s understanding of warehouse hazards and safe working practices.

- Identifying early warning signs of damage

- Employee safety responsibilities

- Best practices for daily inspections

- Reducing long-term risk

Racking Inspection Training

We train your internal staff to confidently perform routine visual inspections, empowering them to prevent issues before they escalate.

- SEMA & HSE Guidelines explained

- Hands-on or virtual sessions

- Certification for participants

- Ongoing compliance support

Digital Inspection Reports

Each inspection comes with a comprehensive digital report that clearly outlines findings, and prioritised actions.

- High-resolution photographic evidence

- Priority-based guidance

- Compliance tracking tools

- Convenient storage and sharing options

Rack Maintenance Course

Our Rack Maintenance Course equips your warehouse staff with the skills to safely repair and replace damaged racking components in line with industry standards.

- Train your warehouse staff to repair your racking

- In-house racking repairs made safe, simple, and cost-effective.

- Empower staff to repair racking safely — cut downtime, cut costs.

Our Comprehensive Inspection Process

A systematic approach ensuring thorough assessment of your racking systems with minimal disruption to your North East England.

Initial Assessment

We begin with a site survey and a review of the HSG76 guidance document to fully understand your warehouse layout, racking configuration, and operational needs.

Detailed Inspection

Our inspectors conduct a systematic examination of all racking components, including uprights, beams, bracing, connectors, and safety accessories, in strict accordance with SEMA standards.

Risk Assessment

Findings are categorised using a traffic light system (Green, Amber, Red) to highlight the level of urgency. Any critical issues are flagged immediately with on-the-spot safety recommendations.

Report

Within 48 hours, you receive a comprehensive digital inspection report complete with photographs, compliance notes, and prioritised recommendations to help you plan effective remediation.

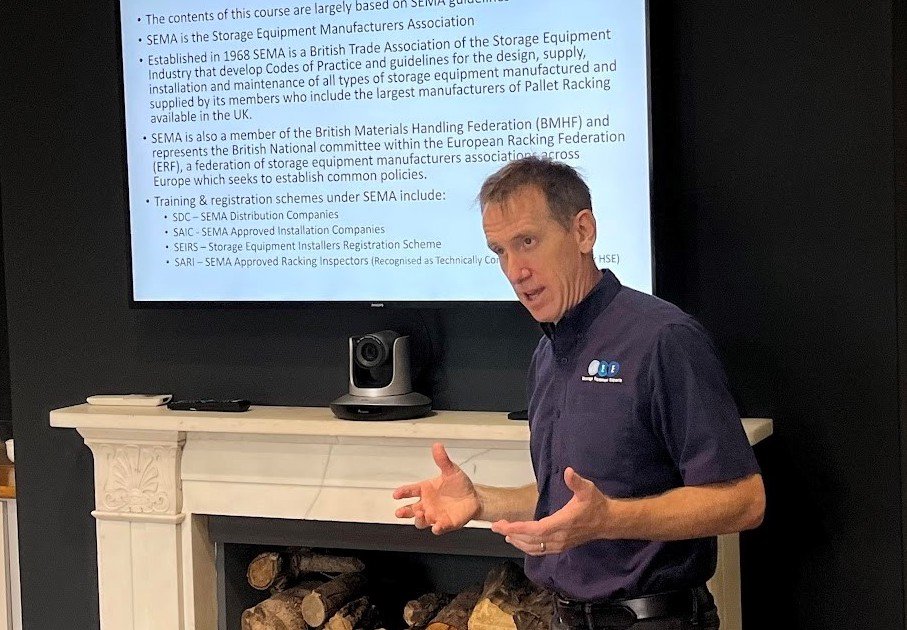

Racking Inspection Training Courses

Our one day racking inspection training courses are provided by SEMA Approved Racking Inspectors and have been assured by RoSPA.

- Enable staff to complete racking inspections to SEMA Guidelines as detailed within HSE Guidance.

- Understand and perform the role of the PRRS (Person Responsible for Racking Safety).

- Essential for forklift operators to increase awareness of the need for safety in relation to racking systems.

- A certificate that is valid for three years is issued on completion of the course.

Training Centre cost: £275 + VAT per person

Online Course cost: £250 + VAT per person

Regulatory Compliance & Standards

Stay compliant with UK health and safety regulations while protecting your business from liability. Our inspections ensure full adherence to all relevant standards and guidelines.

🛡️ HSE Regulations

Full compliance with Health and Safety Executive requirements including PUWER 1998 regulations and Workplace Health, Safety and Welfare Regulations and HSG76 Guidance Document.

🔍 SEMA Guidelines

Adherence to Storage Equipment Manufacturers’ Association code of practice for the design, installation, and use of static steel pallet racking.

👷 Regular Racking Inspections & Staff Training

Scheduled racking safety inspections by SEMA-approved inspectors and staff training to ensure safe warehouse operations and ongoing compliance.

Inspection Checklist

- ✔️ Structural integrity assessment

- ✔️ Load capacity review

- ✔️ Connection point examination

- ✔️ Safety signage review

- ✔️ Damage assessment

- ✔️ Environmental factors

- ✔️ Operational compliance

- ✔️ Documentation review

Frequently Asked Questions

Common questions about racking inspections in North East England.

In the North East, warehouses often encounter issues such as beam damage from forklifts, overloading, corrosion on older racks, and missing safety guards. Regular inspections help prevent accidents, minimize downtime, and ensure your storage systems remain reliable and compliant.

Preparing your warehouse for an inspection is straightforward. Clear the aisles, and provide inspectors with easy access to all areas. Having recent maintenance records on hand facilitates a thorough evaluation of your racking systems.

Yes, even newly installed racking must meet SEMA standards and HSE regulations. Early inspections detect potential structural or safety issues before they become costly problems, ensuring your warehouse is safe from the outset.

Absolutely. Detailed inspection reports demonstrate proactive safety measures, which insurers often require to reduce liability and ensure coverage. Regular inspections can potentially lower insurance premiums by mitigating risks.

The duration of an inspection depends on warehouse size and racking complexity. Most North East England warehouses can expect a complete inspection within a few hours, with a detailed digital report delivered within 48 hours, providing clear recommendations for any required actions.

Need a Racking Inspection or Training? Contact Us Today