Warehouse Pallet Racking

Adopting best practices in industrial pallet racking is essential for the safety of employees and maintaining legal compliance. It also leads to the smooth running of the warehouse and ultimately improves business.

All companies with as little as one bay of racking should be legally compliant and examinations by a qualified SEMA approved inspector should carried out at least once or twice yearly; pallet rack safety inspections form a key part of the process which ensures that businesses remains legally compliant.

It is worth noting that during an inspection, particular attention is paid to beams, uprights, frame bracing, floor fixings and lock in clips as indicated in the SEMA Code of Practice, guideline no. 6. General observations are also made of the following:

Industrial Pallet Racking Locations on Beams

- Conditions and types of pallets.

- Positioning of loads and types of loads stored on pallets.

- General forklift operatives use of the pallet racking.

- Condition and type of floor the racking is fixed on.

- General housekeeping of the pallet racking installation for industrial.

- Possible changes from the original design requirements.

Inspections are carried out from ground level with the visual examination of exterior and other reasonably accessible racking components. If any damaged racking is identified which requires immediate attention, the site contact will be informed of the racking component and its position in the racking installation.

Following an inspection, racking will be categorised into three risks, green, amber and red.

- Green – areas where damage is sufficiently low to allow the continued use of the racking with no further action.

- Amber – areas where the damage is sufficiently severe and warrants remedial work, but not enough to warrant the immediate unloading of the rack. Once the rack is unloaded however, it should not be reloaded until repairs have been carried out. In the event that the storage position is full for four weeks after the initial identification of the problem, the rack should be off-loaded for repair without further delay.

- Red – areas where a high level of damage is identified, exceed the indicated industry standard, which warrants an area of racking being immediately offloaded and isolated from future use until repair work is carried out.

In the case of a red category the pallet racking for industrial should be classified and treated as soon as possible with processes for repair being adopted and worked into daily routines. It is vital to remember that any damage will result in a reduced safety factor of the structure. Employees must pay particular attention to damaged uprights, bracing beams and beam safety pins.

Safety can be integrated easily into employees’ day to day routines. Processes can be worked into the running of a warehouse in a number of ways through training, team briefings and eliminating problems at the source, for example replacing defective pallets before they enter the warehouse racking.

Furthermore, pallet racking managers are increasingly relying on temporary and agency workers who sometimes have little or no prior experience of working in this environment. It is vital that safety training becomes part of the induction process.

Integrating best practice around racking damage is one way to ensure that maximum productivity and safety is achieved. Familiarise workers with the pallet racking systems used and ensure they understand the difference between regular usage (day to day wear and tear) and real damage in order to help them identify potentially dangerous situations early on. Key elements staff should question include:

- Is the racking erected on a sound level floor?

- Is the system installed in accordance with manufactures instructions?

- If secured to a building has this been proved by structural calculations?

- Are double sided runs connected and spaced by using appropriate run spacers?

- Is the racking fixed securely to the floor?

- Are beam connector locks fixed at both ends of the beam?

- Are the correct maximum load notices on display?

- Are all racks in alignment?

- Are the correct pallets being utilised?

- If there is any obvious physical signs of rack damage? Identified damage must be assessed and reported in accordance with the Codes of Practice.

- Is there sufficient protective equipment in use e.g. column guards and rack end protectors?

- Has the handling equipment changed since the original specification?

It is important to share reoccurring safety and damage issues with staff to help find solutions. For example, damage that often occurs with small parts storage can include shelf overloading and warehouse operatives climbing or standing on racking. The most common damage on small part storage is from people standing on the lower shelf to reach the top shelves rather than using the correct access equipment. Under no circumstances should any personnel stand or climb any type of shelving or racking.

Regular visual inspections should also be carried out by staff and documented, with any damage that requires attention being quickly resolved. Staff should be trained to act if damage occurs and affects:

- The cross-sectional profile of a main load beam

- The straightness of beams, bracing, or uprights

- The welds and joints or bolts and clips

Different levels of inspection are required under different circumstances. Upon initially finding damaged racking, a written report must be submitted to the person with responsibility for rack safety in the pallet racking UK.

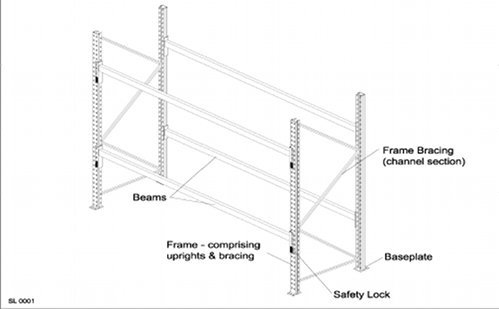

The pallet racking installation in image one comprises of two main elements: the beams – comprising the beam section, end connectors and safety locks, and the frames, comprising uprights, bracing and base plates.

The pieces of pallet racking that will be reviewed during an inspection are outlined below (also see image below).

As previously stated, it is of the utmost importance to report all damage to ensure the necessary precautionary actions are taken.

It is not recommended to repair damaged rack components any component no longer fit for use should be replaced on a like for like basis. If the bottom portion of an upright is damaged, replace the whole upright up to the original splice level. Do not cut and splice in a small piece of upright and never apply heat in an attempt to straighten bent components.

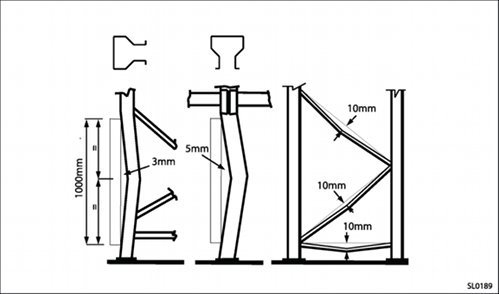

Similar to racking, SEMA quantifies damage to frame uprights and bracing as green, amber or red risk. These rules only apply to damage that produces an overall bend in a component and do not apply to highly localised damage such as dents, buckles , tears and splits. Bends are judged against a 1000mm straight edge, localised bends over a shorter length should be judged pro-rata, i.e. over a half metre length half the limit applies. Racks subjected to tears and splits should be replaced.

It is worthwhile training staff on the following methods of measuring damage (also see image below):

- A 1000mm steel straight edge is placed against the flat surface on the concave side of the damaged component such that the damaged area lies equidistant from both ends

- For an upright bent in the direction of the rack beams, the maximum gap should not exceed 5mm

- For an upright bent in the direction of the frame bracing, the maximum gap should not exceed 3mm

- For an upright that has been damaged in both directions, the damage shall be measured and treated separately and the appropriate limits observed.

- For bracing members bent in either plane, the maximum gap should not exceed 10mm. Pro-rata for bracing members less than 1000mm long.

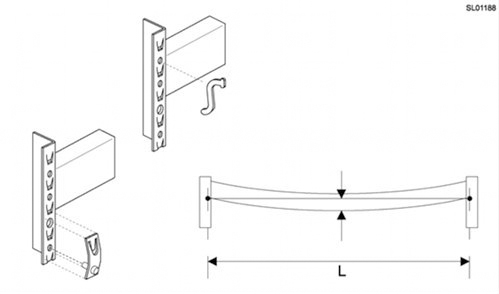

Further advice on damage to pieces of racking includes (also see image below):

Safety Locks

- If missing, these must be replaced immediately

- If miss positioned these should be reposition immediately, when correctly positioned the pin should pass through the lock hole in the connector and through the top of an upright slot

- Damaged locks should be replaced

- If the upright slot is damaged the top of an upright slot may become damaged by the safety lock pin, if the beam has been raised. If damage has occurred the beam should be repositioned (up or down) on the upright so that the pin fits through an undamaged slot.

Beam End Connector

- Any damage to a connector should result in the beam being replaced immediately, if the upright slots are also damaged, these slots should not be reused for beam location

- Wield damage such as cracking or lifting of the weld should result in the beam being immediately replaced

Beam Section

- If damage effects the section shape the beam should be replaced immediately

- If the vertical beam deflection is more than SPAN/200* the beam is overloaded, remove the load and check against permissible load data.

- If the beam is permanently bowed when unloaded it has been overloaded. A straightness tolerance of 1 in 1000 is permitted. If the unloaded beam bow is more than SPAN/1000**, vertically or horizontally, it must be replaced.

All industrial racking brings the obvious potential for damage by vehicles. In places of repetitive damage, install rack protection. Proper guidelines for forklift truck traffic, maintaining good housekeeping and improving lighting can also help prevent damage to pallet racking and should be part of best practice.

Back strains and injuries are common concerns in warehousing, shelving and storage solutions can be installed which allow access and retrieval of stock at a comfortable, ergonomic height. Products such as vertical storage machines or pallet racking pull out units are ideal for this as they are designed to present stock at an optimal height and allows stock to be reached without straining.

Integrating best practice and partaking in regular inspections keeps staff safe in the workplace, reduces downtime lost to accidents and faulty equipment, and eliminates the risk of fines for non-compliance, improving business operations, growing profitability and increasing competitive edge.

* Deflection greater than SPAN/200 when loaded: Overall beam length divided by 200 is the maximum allowed deflection when the beam is loaded i.e. for a 2700mm beam/200 the beam can deflect 13.5mm when loaded to comply with the SEMA guidelines.

** Deflection greater than SPAN/1000 when unloaded: Overall beam length divided by 1000 is the maximum allowed deflection after the beam is unloaded i.e. for a 2700mm beam/1000 the beam can deflect 2.7mm when the load has been removed to comply with the SEMA guidelines UK.