Racking health and safety refers to the health and safety guidance specifically surrounding your storage equipment. HSE’s HSG76 outlines best practice for this, but we’ve also broken it down here as well.

Most Racking Health & Safety is Outlined on Load Notices

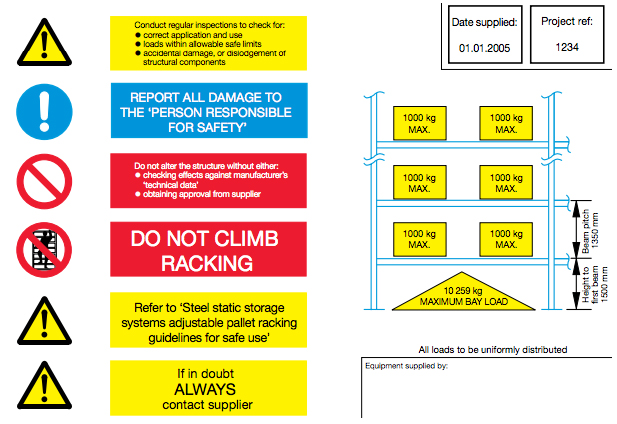

Load notices are a key tenant of racking health and safety. By looking at them, you can get a quick reference for best practice for racking health and safety. They are a legal requirement on all racking systems. Specifically, load notices in Ireland and the UK should look as they do below:

This load notice is designed specifically for pallet racking (the blue diagrams in cantilever racking load notices would look slightly different) and they are crucial for pallet racking safety. This layout is approved by HSE, SEMA, HSA and the EU. It explains how much weight the racking system can take, as well as other vital pieces of information.

Do not overload Racking or Climb on Racking

These are the two most important takeaways from the load notice and they are also related. Sometimes, people feel that it’s okay to climb on racking because there are some racking systems which are specifically designed to be climbed on. However, these systems are not standard and it will be abundantly clear that they are designed with a safe climbing system.

In all other cases (of if you are at all unsure) you shouldn’t climb on a racking system. Load notices help to make this clear. The reason racking systems shouldn’t be climbed on is related to overloading.

Most businesses like to make sure they are using a warehouse to its full potential. Of course, this doesn’t mean overloading the system. Rather, you want to give yourself a lot of leeway with regards to the amount your system is currently storing. The second you put some or all of your weight onto the system, though, this all goes out the window. So, don’t do it.

Assign a Person Responsible for Racking Safety (PRRS)

A person responsible for racking safety is the person in your warehouse who is competent enough to perform regular staff-led racking inspections (as recommended by HSE and the EU). They should also be competent enough to do so (as is legally required according to the CDM Regulations).